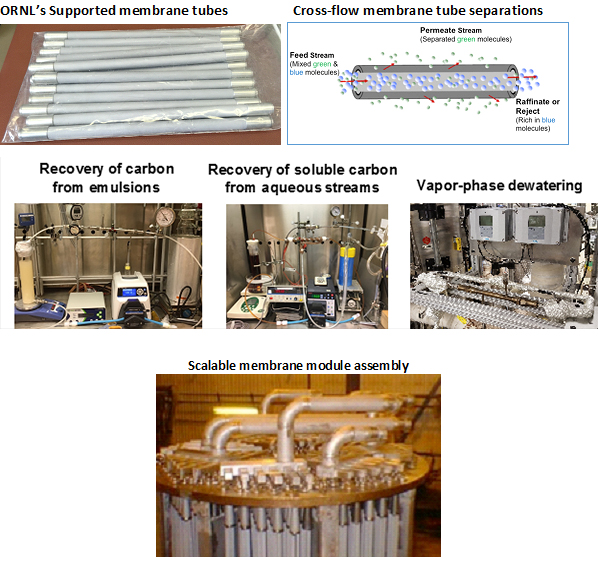

| Overview | ORNL develops a new class of surface-engineered (superhydrophobic or superhydrophilic) nano/meso/micro-porous membranes that can be tailored for high permeation flux, high selectivity, and anti-fouling separations performance. The membranes developed include inorganic (ceramic or metallic) porous materials based or supported polymer or polymer-graphene coated membranes. They can be tailored for either liquid phase separations (emulsions, chemicals, or dewatering/deionization) or vapor phase separations (such as for the hot pyrolysis vapor processing for production of biofuel and value chemicals). The separations with the tubular membranes’ platform can be operated in continuous cross-flow separation mode. In addition, nanocatalysts can be deposited on the membrane tubular platforms to serve as membrane reactors for high-yield reaction processing.The planar or tubular membrane platforms (either single-tube or multi-tube modules) can be fabricated and bench-scale tested at ORNL or at the industrial lab settings. The multi-tube module is proven a scalable, mechanically rugged, and high-temperature tolerant assembly system. ORNL has the inorganic membrane fabrication center, the nanomaterials engineering and functionalization research laboratory, and is the home for DOE user facility Center for Nanophase Materials Sciences (CNMS) for advanced materials characterizations. ORNL has past experiences to support industrial R&D to solve practical separations/catalysis problems. ORNL work with NREL for a real-time MBMS-monitored membrane vapor separation test facility. |

| National Laboratory | Oak Ridge National Laboratory (ORNL) |

| Additional Information |

A. Church and M. Hu, “Novel Porous Ceramic Tube-Supported Polymer Layer 3 Membranes for Acetic Acid/Water Separation by Pervaporation Dewatering” Separation and Purification Technology Volume 236, 1 April 2020, 116312 A. Church, Andrew Lepore, Jae-Soon Choi, Zhenglong Li, Kim Margrini, Mark Javis, Felipe Polo Garzon, Zili Wu and Michael Z. Hu. Acetic Acid/Propionic Acid Conversion on Metal Doped Molybdenum Carbide Catalyst Beads for Catalytic Hot Gas Filtration. Catalysts 8 (12), 643 (2018) Michael Z. Hu,; Chaiwat Chaiwat Engtrakul; Brian L Bischoff; Mi Lu, Mussie Alemseghed; Surface Engineered Inorganic Nanoporous Membranes for Vapor and Pervaporative Separations of Water-Ethanol Mixtures, membranes 8 (4), 95 (2018). US Patent 9,308,501 B2, “Super-surface selective nanomembranes providing simultaneous high permeation flux and high selectivity”, Date of Patent: April 12, 2016. Inventors: M.Z. Hu, J.T. Simpson, T. Aytug, M.P. Paranthaman, M.R. Sturgeon. U.S. Provisional-Patent Application (on January 25, 2016), Application No. 62/286,65; Title: Integrated Membrane-Pyrolysis-Catalytic Upgrading Systems; Inventors: M.Z. Hu, B.L. Bischoff, C. Engtrakul, M.F. Davis. |