| Overview |

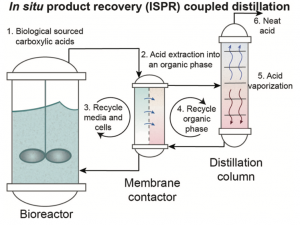

In Situ Product Recovery (ISPR) is a form of process intensification wherein product is separated from a bioreactor as it is produced from the microorganism. ISPR has many process benefits including increased titer, rate, and yield by ameliorating end product inhibition, reducing bioprocess water footprints and reducing overall separations train energy footprint. Researchers in the Bioprocessing Separations Consortium are advancing ISPR technology by developing systems that can operate in high solids environments, reduce chemical consumption demand, reduce energy demand through novel heat integration strategies. |